Discover our

Pay-per-print

Our low-cost, high-resolution 3D printing technology capable of delivering prints on demand.

-

Order a single or small batch of prints.

-

Customized printing and price – tailored to your need.

-

Fast service and delivered prints within the same week.

-

Ideal for new tests or proof of concepts.

Subscription model

Experience our technology through unlimited access to our 3D printing technology.

-

Get the full mycro3D experience of product R&D.

-

24/7 access to our 3D printing service.

-

Iterate designs at an accelerated pace.

-

Ideal for continuous R&D and larger projects.

Complex things done easy

Follow the procedure of how we make your ideas come to life. With minimal effort and maximum design freedom, mycro3D brings inventions from digital to practical.

Generate

The process starts on your own computer, using any CAD software. Here designs are created as with any 3D structure. We believe the most important step of production is designing, so the creator should have the comfort of their usual ways. The structure is then uploaded to a slicing software. We have programmed our printers to work with G-code, allowing us to easily implement the structure into our system. In the slicing software, resolution, size, filling-style, and similar parameters, are selected, and the workpiece is ready for our printer.

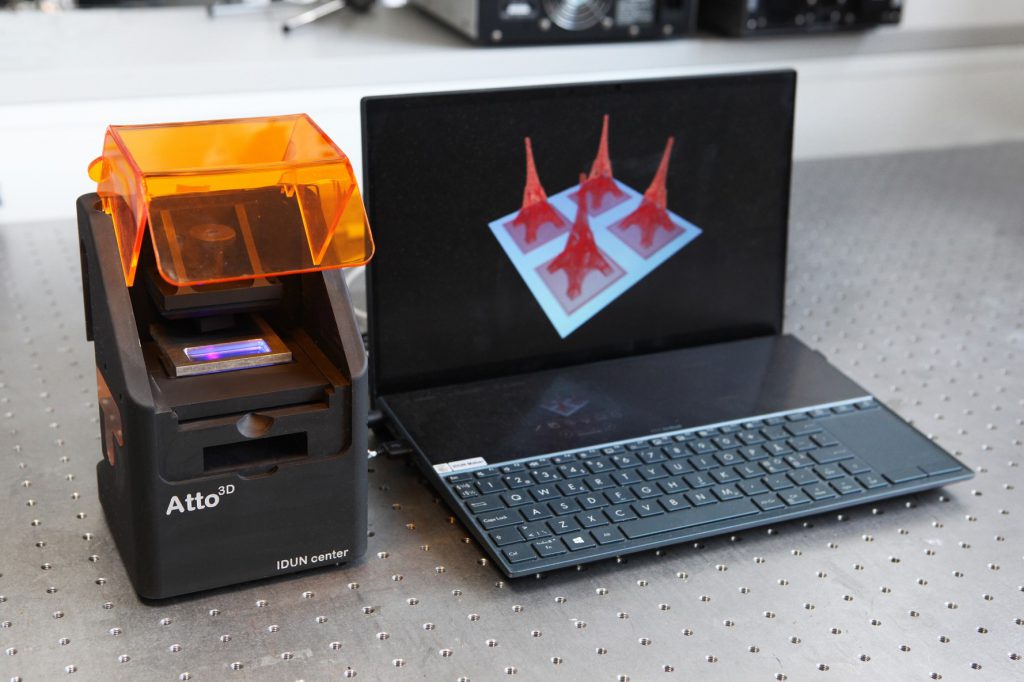

Upload

Here is where attention is turned to the mycro3D printing technology. Choose the desired material to fill up the tank. The printer is automatically set and calibrated between each print, ensuring nanometer precision and the highest resolution for each of your prints. It makes repeatability a cumbersome task with our system. When the desired substrate and vat is loaded, and the system has been calibrated, the printer makes sure your idea will be produced in the best manner possible.

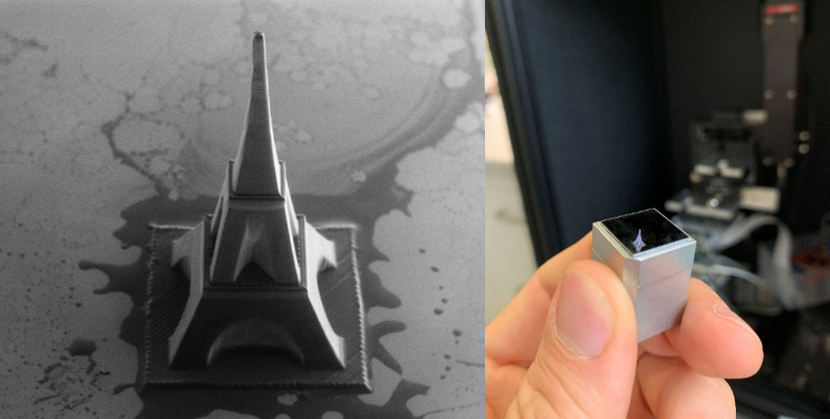

Acquire

After “liftoff”, your product is ready for implementation. Depending on your design strategy, post processing can consists of a rinse followed by a post curing to ensure solidification of material. Nothing unusual for photopolymerization. The substrate platform and in-situ calibration removes the need for support structure. On the contrary, printing can be done directly onto patterned or premade surfaces. This means that the workpiece you design will be ready from the get-go.

Technology

Redefining microscale 3D printing

mycro3D technology builds in the concept of stereolithography, but instead of depending on scanning mirrors, we have reduced the size of our optics down to a scale where we can comfortably move it with nano-position stages. This enables smooth printing and the highest resolution over the entire printing surface. Thus, we obtain stitchless micro- and nanoscale 3D printing for volumes only limited by the range of our position stages.

This has also allowed us to build a more compact and stable system, reaching higher volume, precision and print speed at a lower cost. Some exclusive features mycro3D offers are:

- Versatile material selection through multiple curing lasers (405/650/780 nm)

- Multi material printing by interchangeable resin vats.

- Environmental control box to ensure ideal printing conditions.

- No need for clean room conditions or tedious processes.

A bottleneck to high resolution stereolithography is the scaling problem. As printing voxels are decreased, print time increases cubed, meaning high resolution 3D printing is extremely slow. mycro3D features variable print resolution. Volumetric parts and fillings can be done with coarse printing settings, while finer details can be made with sub-micron precision, saving both time and energy.

Interested? Suggest a use case

We believe that mycro3D has an endless list of potential applications, and we would love to prove this. If you are interested in seeing what we can do, have an ideal application for mycro3D or are looking for a collaborative work with your project, please feel free to connect with us, and together we can make your idea come true. Click below to reach out to us about a print sample and get one step closer to realizing your idea.